Robotics & AI Define the Future of NJ’s Manufacturing Industry

An aging workforce with a lack of young, skilled labor accompanied by the costly nature of New Jersey’s business climate could be two key factors contributing to the decreasing presence of manufacturers in the Garden State.

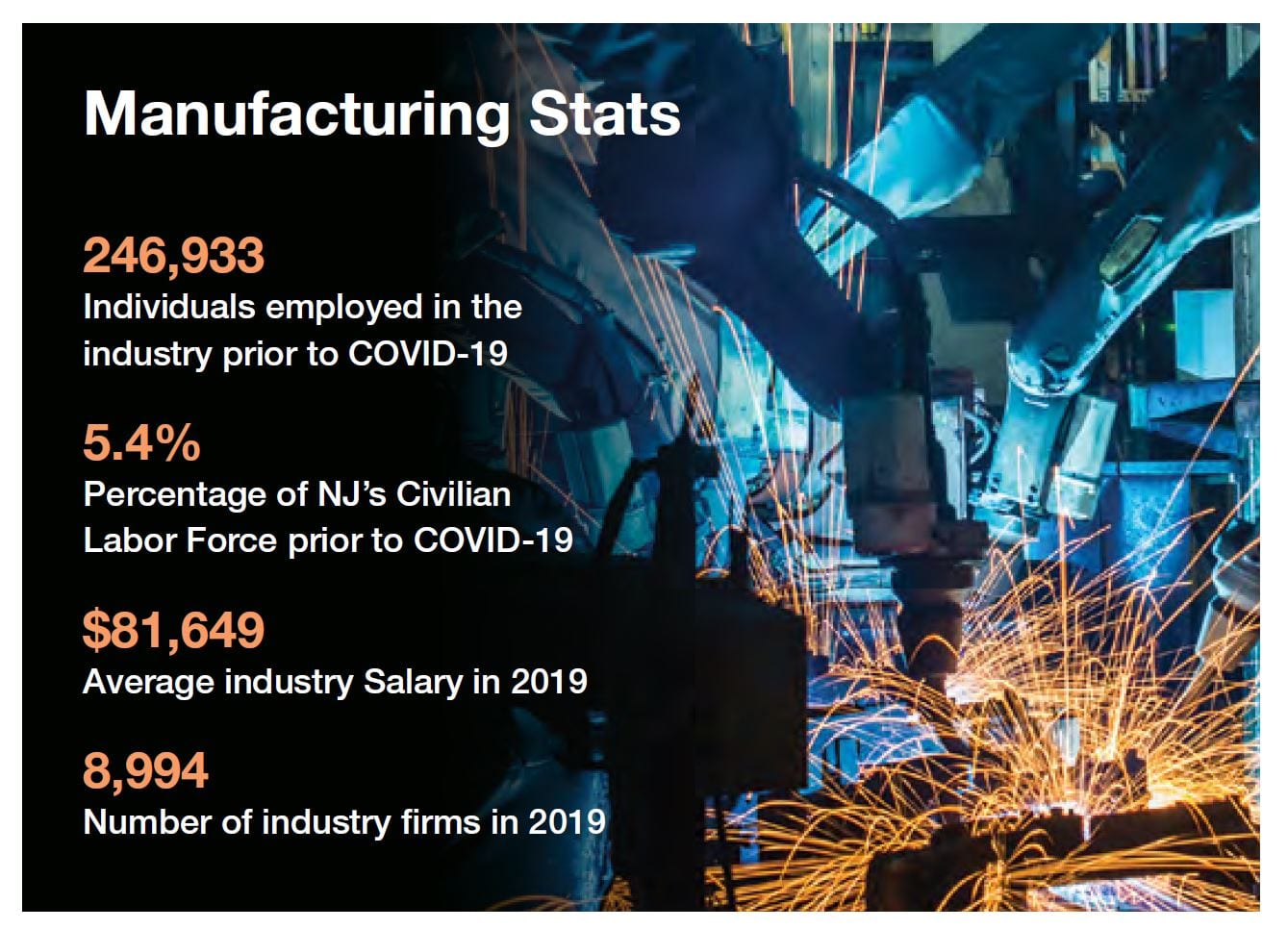

Trends: The manufacturing industry lost 6,464 jobs (or 2.5% of total industry employment) from 2010 to 2019, with total employment declining to just under 250,000 jobs in 2019, according to the US Bureau of Labor Statistics (BLS). Prior to COVID-19, the industry employed 246,933 individuals or 5.4% of the state’s civilian labor force, according to the BLS.

The number of manufacturing firms also decreased from 9,941 in 2010 to 8,994 firms last year. Losing 9.5% (or 947) manufacturing firms in a single decade is a trend that suggests a weakening state-level industry.

Wages: On average, a manufacturing worker in New Jersey earned $81,649 in 2019, an increase from $74,123 in 2010, according to the BLS. Workers in Mercer County earned the most, with average earnings of $130,321 in 2019,

Wages: On average, a manufacturing worker in New Jersey earned $81,649 in 2019, an increase from $74,123 in 2010, according to the BLS. Workers in Mercer County earned the most, with average earnings of $130,321 in 2019,

while workers in Cape May County were paid the least, earning an average $35,990. Average annual wages varied greatly by county in 2019. For example, Morris ($100,251), Somerset ($121,930), and Mercer ($130,321) earned, on average, more than six figures, while Cape May ($35,990), Cumberland ($54,609), and Hudson ($58,125) counties earned on average less than $60,000 in 2019. Cape May County is the only county in New Jersey to have manufacturing workers earn, on average, less than $50,000 in 2019.

Innovations: According to Focus NJ’s Future of Work – Industry Series Study, the increased integration of technology and artificial intelligence, such as robotics, is allowing for increased productivity and decreased timelines. In addition, the increased use of data analytics in everyday production allows for increased accuracy and efficiency. And the integration of cloud computing as a standard workforce skill set will aid in the support of robotics and artificial intelligence.

Skill Sets for the Future: Technological advancements have brought dramatic change to the industry’s operations, business models, and profit-making. As such, the skill sets for the future of manufacturing jobs has dramatically shifted as well. According to the Future of Work – Industry Series Study, skill sets of the future include trade skill sets (such as machinists, mechanics, mechanical engineers & technicians), robotics, cybersecurity, information technology, big data, analytics, cloud computing, simulation and virtual reality. The demand for increased skill sets provides workers in the manufacturing industry the opportunity to up-skill and re-skill to earn more money.

**This content was originally created for the NJ Business Magazine**